Quality is our utmost concern and our processors have perfected a comprehensive set of standards and guidelines that are scrupulously maintained on each project. We supply the best quality clean packaging materialsavailable to the highest standards in an increasingly demanding global market

All our products are manufactured in a state-of-the-art class 100 clean room, providing a full spectrum of contamination control services and supplies. Our products are packaged in airtight double or triple-barrier sealed overwraps bearing a Certificate of Conformance to government or NASA Clean Room Products standards.

Operational Standards:

Federal Standard No. 209 Clean Room and Work-Station Requirements, Controlled Environment, latest revision.

ASTM No. F25-63T Sizing and Counting Airborne Particulate Contamination in Clean Rooms and other Dust Controlled Areas Designed for Electronic and Similar Applications.CRS 25: General Facilities Document and Production/Quality Process for Clean Film Production and Packaging.

NASA Specifications JPG 5322.1, JSCM-5322, JSC-C-25, MSC-C-25 and KSC-C-123J Surface Cleanliness Levels for Precision Packaging Materials.

Military Specifications: B22191C Barrier Materials Transparent, Flexible, Heat Sealable; 1246 Product Cleanliness Levels and Contamination Control Program.

Federal Specification A-A-3174 Commercial Item Description, Plastic Sheet, Polyolefin (supersedes Federal Specification L-P-378 Polyethylene Film Thin Gauge).

SAE-ARP-743 Procedure for the Determination of Particulate Contamination of Air in Dust Controlled Spaces by the Particulate Count Method.

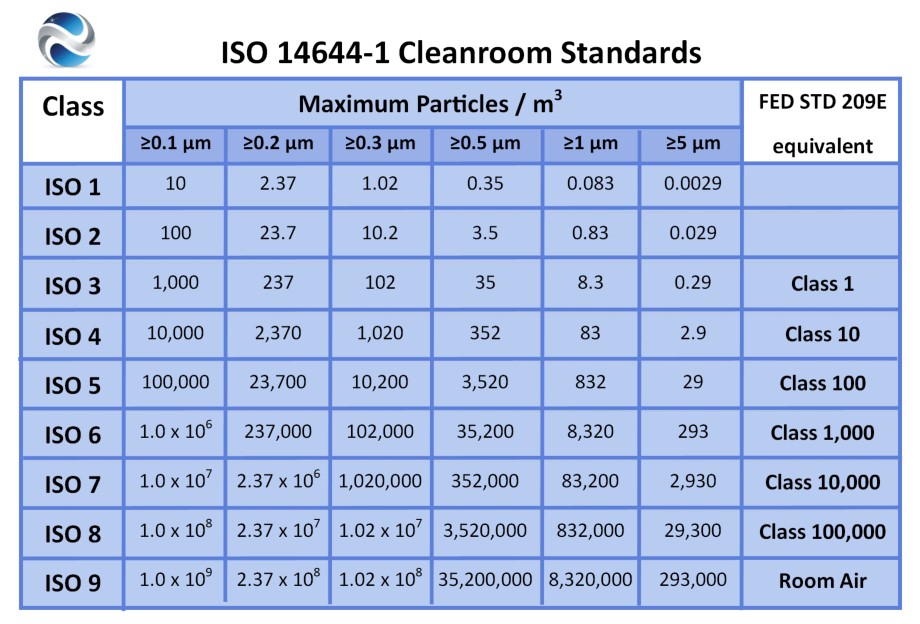

Cleanroom Classification

Cleanrooms are classified by how clean the air is. In Federal Standard 209 (A to D) of the USA, the number of particles equal to and greater than 0.5mm is measured in one cubic foot of air, and this count is used to classify the cleanroom. This metric nomenclature is also accepted in the most recent 209E version of the Standard. Federal Standard 209E is used domestically. The newer standard is TC 209 from the International StandardsOrganization. Both standards classify a cleanroom by the number of particles found in the laboratory’s air. The cleanroom classification standards FS 209E and ISO 14644-1 require specific particle count measurements and calculations to classify the cleanliness level of a cleanroom or clean area. In the UK, British Standard 5295 is used to classify cleanrooms. This standard is about to be superseded by BS EN ISO 14644-1.

Cleanrooms are classified according to the number and size of particles permitted per volume of air. Large numbers like “class 100” or “class 1000” refer to FED_STD-209E, and denote the number of particles of size 0.5 mm or larger permitted per cubic foot of air. The standard also allows interpolation, so it is possible to describe e.g. “class 2000.”

Small numbers refer to ISO 14644-1 standards, which specify the decimal logarithm of the number of particles 0.1 µm or larger permitted per cubic metre of air. So, for example, an ISO class 5 cleanroom has at most 105 = 100,000 particles per m³.

Both FS 209E and ISO 14644-1 assume log-log relationships between particle size and particle concentration. For that reason, there is no such thing as zero particle concentration. Ordinary room air is approximately class 1,000,000 or ISO 9.